Designing a racing buggy takes more than four good wheels and a little luck. It takes expertise, teamwork and dedication.

A perfect mixture of mechanical engineering, computer science and business savvy, Seattle Pacific University’s Baja team is bringing together students of many backgrounds for one central goal: make the best buggy. Over the course of the next year, SPU’s team will utilize the diverse skill sets of its roster to create a buggy and business pitch capable of overtaking college teams from across the country.

This year, the team already has their buggy mostly complete. In fact, it could race right now. The team is shifting to a two year development schedule, which allows them to train new members on the current car while having more experienced members design next year’s buggy. In opposition to last year, where the one year turnaround cycle made it difficult to train new members.

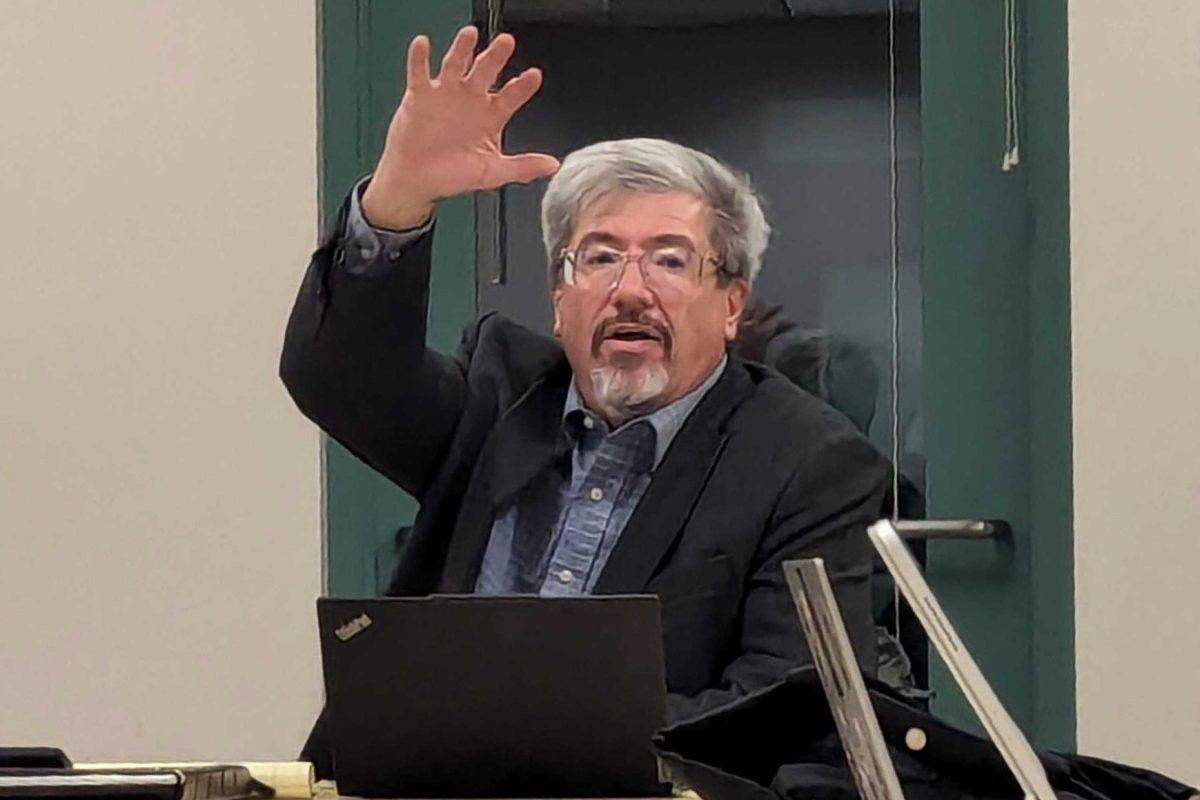

Technical Director Gideon Priest, a junior and mechanical engineering major, is working to make the club more accessible.

“The goal this year is to help people learn and understand how to be a part of a bigger team,” Priest said. “Last year, it was kind of daunting coming in and trying to learn new things. They just gave you a task and were like ‘here you go’ and, if you didn’t do it well enough, they’d come in and do it for you.”

Development of next year’s buggy will be greatly benefited by a sponsorship from Honeywell, one of the largest engineering companies in the world. The company will give the team access to a four axis CNC machine, a tool which will allow the team to develop a brand new transfer case. This will allow for better power transfer from the transmission to the axles, meaning the buggy has improved acceleration on uneven terrain.

“In the past, we haven’t had the resources available to build [a transfer case] because it takes a four axis CNC machine,” Gideon said. “We don’t have that, they do. Being able to work with them on that is going to be super helpful.”

With SPU’s Baja team being one of the few college teams that has gotten a tour of Honeywell’s facilities, the opportunity to work with Honeywell is about more than just winning—it’s about real world training.

“They’re basically teaching us the engineering process, like how we’d essentially be doing something in the real world, which is preparing us for our jobs which is awesome,” Priest said.

Engineering the buggy is only half the battle. A significant part of the challenge is building a professional pitch for how one could profitably manufacture a theoretical version of the buggy.

Sophomore business administration major Emilio Elmonei is a member that is ready to take on the challenge.

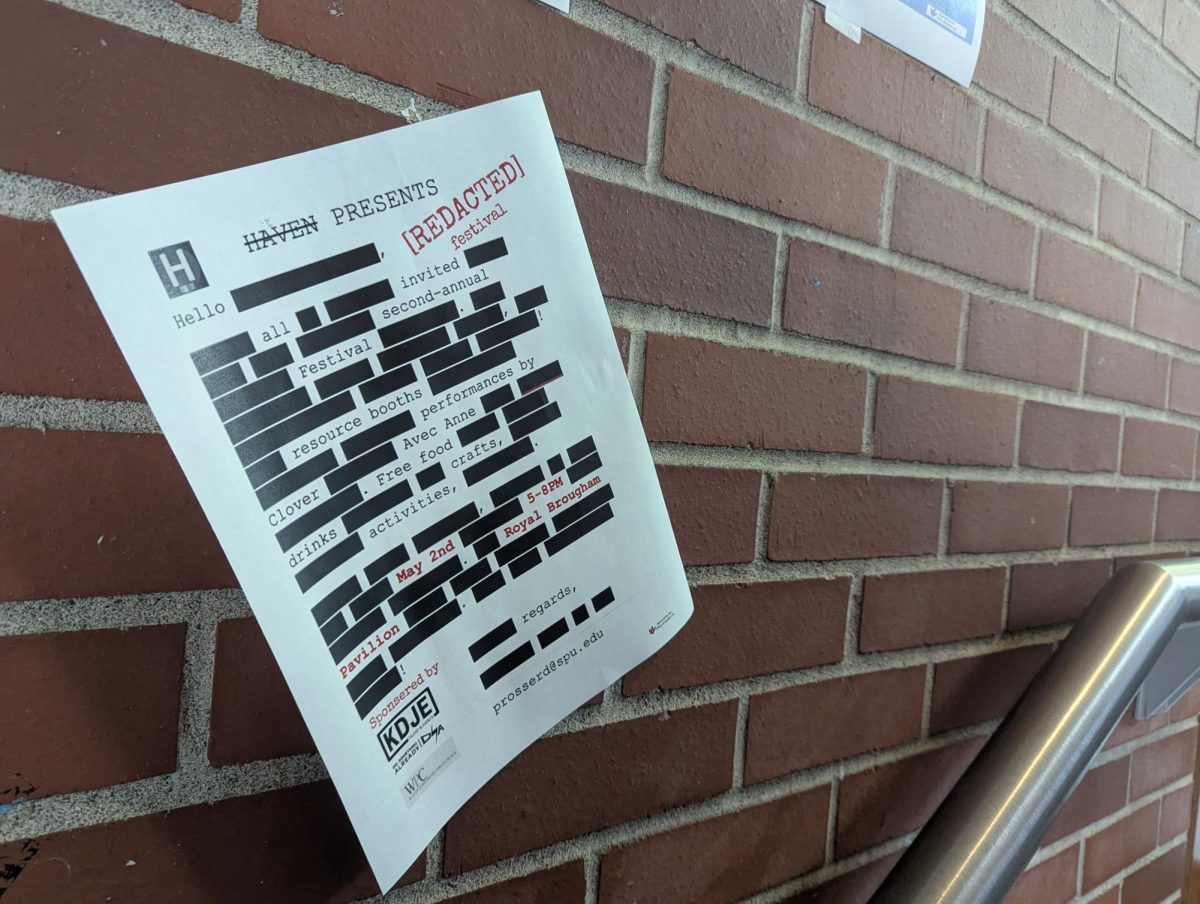

“This is actually the first year we’ve actually had a business team,” Elmonei said. “[We’re] working on marketing and advertisement and putting up signs and posters, so we’ll be going around Seattle with those posters that we designed.”

The business team is given a budget, a special prompt for the car and a plan for how to develop it. This year’s prompt sees the team detailing a buggy meant for a multinational defense company. The team must detail a plan to design, manufacture and make a profit from the car. Additionally, they are tasked with designing a fictional company — including such details as location, employee diversity, realistic timelines and a proposal for prototype testing.

Falcon Racing won’t begin competing until the spring but, in the meantime, they will have plenty of work cut out for them. The work can be complicated, but in the end, it is all about creating a good learning experience for those participating in the club.

“Our goal this year is to make a welcoming environment. We want to work with you to help you learn, because that’s ultimately the college experience,” Priest said.